stuka

Sergeant

The one and only

The one and only

Posts: 1,205

|

Post by stuka on Mar 2, 2013 17:56:47 GMT -5

I will explain more later but here is a picture of it, was going to upload a video of it firing but i accidentally deleted the freaking video >=( When i buy more vn mid's i will show step by step instructions and maybe a vid, but here is a pic to show it works oi47.tinypic.com/1128kys.jpg |

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Mar 2, 2013 18:58:05 GMT -5

That's wonderful. What brand vn mids did you use ? do they slide right into the BAR mag housing once the BAR guts are stripped out? Do the inner guts of the M16 vn mag guts have to be removed first?

This is a project I intend to tackle but I was hoping some other brave soul would break brush and I could take the slack position.

|

|

stuka

Sergeant

The one and only

The one and only

Posts: 1,205

|

Post by stuka on Mar 3, 2013 0:07:27 GMT -5

It's more complicated then just sliding in, took ~2 hours in total to get the first mag set up properly to work, but now my dad and i know what we are doing. Since i don't have another vn mag and i just got back from a party a party i won't be able to show complete step by step but i'll take a pic of a stanag with approximate cutting/shaving points.

The VN i used was i believe a MAG brand mag(Lol)

|

|

stuka

Sergeant

The one and only

The one and only

Posts: 1,205

|

Post by stuka on Mar 3, 2013 0:28:21 GMT -5

Approximate shaving points oi48.tinypic.com/2ibia2q.jpgThe bar mag will need to be opened up to fit mag in initially but when shaving is done properly you should be able to squeeze it back in to place. Like i said, you will have to wait for more accurate numbers but this is the basic idea |

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Mar 3, 2013 21:26:30 GMT -5

I assume you're using the longer m16 mag just to show the shave points since clearly it's the shorter vn length mags that you want to use for this conversion. If so i will get some of the MAG brand vn style midcaps ordered. Do you just epoxy them into place once they are in place?

|

|

stuka

Sergeant

The one and only

The one and only

Posts: 1,205

|

Post by stuka on Mar 3, 2013 22:03:52 GMT -5

no,actually it is pretty snug,wobbles a little vertically but the feeding nozzles adjusts it as necessary if at all.

The stanag is just for show.Since i don't think i'll be getting any tomorrow I will try to get the best measurements off of the stanag if you want

That may not happen until tuesday since my dad wants it to be perfect and what not Lol.

I used my mid-cap today and I liked it more then the high's, ran through all my mags though in one game haha, had more trouble with the hi's then my mid.

The thing that i like about the MAG brand is that they are grey so you can mark them much easier but i don't think it would need to be mag brand specific

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Mar 3, 2013 23:11:50 GMT -5

I have had great luck with all the MAG brand mags I have bought so that is definitely my preference. I detest high caps so I will swap over to these mid caps as quickly as I can. In looking at the high cap set ups it appears they essentially stuffed a m16 vn highcap into the BAR metal outer shell. Which leads me to wonder if actual BAR mags can be sourced inexpensively would that maybe be a cheaper way to GO?

|

|

stuka

Sergeant

The one and only

The one and only

Posts: 1,205

|

Post by stuka on Mar 4, 2013 18:29:47 GMT -5

What do you mean by that?

|

|

|

|

Post by Atomic Racoon on Mar 4, 2013 19:34:03 GMT -5

I think he's saying a real steel BAR mag could be used. That's a great idea, except for the inexpensively part. I've not come across "inexpensive" BAR mags, well, ever to be honest.

|

|

|

|

Post by Atomic Racoon on Mar 4, 2013 20:09:22 GMT -5

Actually, Numrich has a few for under $40 a piece. www.gunpartscorp.com/Products/1153060.htmIf someone could make a silicon mold of the shell, they could produce them cheaply I think. Or make them out of styrene/ABS sheet. |

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Mar 4, 2013 20:54:04 GMT -5

unless you believed you were going to sell a whole bunch of them at something that actually reflects a profit you'll be quite a while before you see a return on your mold expenditure. I have seen BAR mags at the gun show for $20.00 $25.00 each so rather than buying the Echo BAR mags and the VN midcap guts it would be perhaps cheaper to use the real parts assuming they fit in the gun.

|

|

stuka

Sergeant

The one and only

The one and only

Posts: 1,205

|

Post by stuka on Mar 6, 2013 17:38:51 GMT -5

here is the inside measurements (In decimal inches) oi46.tinypic.com/2w5uk9u.jpgBasically, the vn mag will need to be shaved to those measurements to fit(Well, slightly smaller to actually fit lol, thats just the amount of space you have, subject to small variations in each bar mag though). If you need me to expand on each measurement then let me know. This is where the real text info about conversions is, Tools used; Flat head(x2 or more or you can use some other prying device), philips head, pliers, a table vice and a dremel. Step 1; Take the philips head and unscrew the bottom, then take your pliers and pull the bottom off, you may need to push up on it with the flathead to get a grip.You pull that off and then you should be able to get the insides out, just tilt and turn it if need be, should slide out. Step 2;This is where the measurements come in handy.(it helps to use the vice) Dremel the magazine in the specified areas to those measurements as necessary(may need more or less depending on how the bar mag was molded and what not). Step 3; this is where you use the flatheads or some other prying device and pry open the BAR mag and then you should be able to put the mag in it, hopefully it's not too easy or the mag might not stay in place inside the BAR mag. The feeding lip should be pretty 'flush' with the hole in the BAR mag, if it is up it might not feed. Unfortunately, at least when i did it, we were not able to put the bottom back on because it pushed the vn up to high.(If necessary[probably will be], you may need to use the vice to tighten it back up so that it will actually fit in the BAR mag well and lock in place) Sounds simple but don't take it likely. It took about two hours to get the first mag to work but i can imagine that now I should be able to get it done in ~20 minutes or less. If you need any other info, other then pics, like i said, let me know and comment on here. |

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Mar 6, 2013 20:21:49 GMT -5

I have ordered a box of the MAG brand Vietnam M16 mags. I am anxious to get these done. If somehow i am unable to get them done I wanted some VN M16 midcaps anyway! just to be sure thse are Marui compatible m16 mags were are looking for right. Its a little hard to tell looking in through the top of the BAR high cap mag as they have a different looking upper piece as part of the BAR mag.

|

|

|

|

Post by jeeperscreepers on Mar 12, 2013 10:31:49 GMT -5

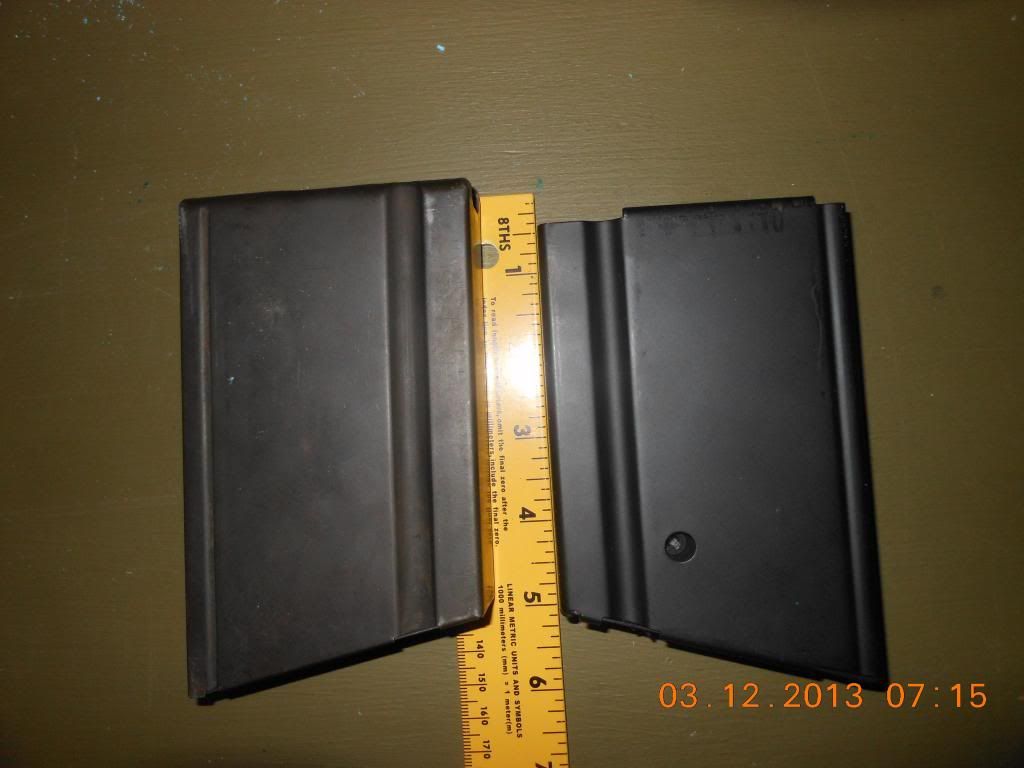

Hi Guys, I was able to borrow a real BAR magazine and compared it to the airsoft one. My original plan was to get one so that I can replace the airsoft one for display since the airsoft mag had this annoying hole on the left side. The original mag fits in the Echo 1 BAR magazine well but will not lock. It is kept in place by friction. The original mag protrudes a little bit lower than the locked airsoft mag. The airsoft magazine is dimensionally shorter than the real magazine and the magazine locking notch does not align with the magazine catch. If you plan to use a real mag shell to convert to an airsoft magazine you might be in for some work which might make buying the airsoft mag more economical. Functional BAR mags, as I was told, are in the $30 to $40 range. Magazine top: Original magazine with follower and dummy round.  Original magazine with out follower  Back Spine and magazine locking notch  Close-up detail magazine locking notch. The original mag locking notch will have to be filed to lock properly with the magazine catch or vice versa.  There is about a 1/2 inch difference in the vertical dimension. So you might have to take off about a 1/2 from the top of the Original mag so that it will sit properly in the Echo 1 mag well.  Airsoft Mag seated in mag well  Original mag seated as far as it will go in Echo 1 mag well  I hope this helps JC |

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Mar 12, 2013 17:35:45 GMT -5

That helps a ton! Thanks for posting.

|

|

stuka

Sergeant

The one and only

The one and only

Posts: 1,205

|

Post by stuka on Mar 14, 2013 8:38:22 GMT -5

Has anybody tried my way yet or made a new way or what?

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Apr 6, 2013 0:06:01 GMT -5

I am going to tackle this, this weekend i got a pack of seven MAG mid caps so hopefully the learning curve will assist with each new conversion. Your photos and instructions are a huge help.

|

|

stuka

Sergeant

The one and only

The one and only

Posts: 1,205

|

Post by stuka on Apr 6, 2013 16:57:33 GMT -5

no problem, just be sure to tighten the bar mag properly other wise it won't click properly

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Apr 6, 2013 18:46:07 GMT -5

Not sure quite what you mean by that? I used a thin strip of ABS plastic to further snug things up and converted all seven of my magazines. They all work great. So much nicer than the hi caps. I now have the hi caps innards which should work well in a couple box mags i am building

|

|

stuka

Sergeant

The one and only

The one and only

Posts: 1,205

|

Post by stuka on Apr 6, 2013 21:27:23 GMT -5

well then lol

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Apr 7, 2013 0:18:33 GMT -5

This was a very straight forward and simple project. It really helped that someone had broken ground by doing it first and shared their experience. Thanks Stuka! The fact that the BAR mag has that existing "roof" inside the mag really hlps to insure that everything lines up as it should. I find you do need to put some sort of spacer between the m16 inner mag and the bar mag slide in base plate. I use a tab of appropriately thick abs plastic that i glue to the bottom of the m16 mag. Without it the inner mag sometimes slides down when you load it and doesn't feed. With the plastic base and the base plate in place they are rock solid and feed super.

|

|

stuka

Sergeant

The one and only

The one and only

Posts: 1,205

|

Post by stuka on Apr 8, 2013 8:10:25 GMT -5

No problem but now I hotta fix my BAR trigger contact is well iffy

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Apr 8, 2013 12:52:06 GMT -5

On my BAR itself I've got to refinish the plastic butt stock in order for it to look less plasticky. It also cracked although i haven't a clue how that happened. It functions just fine. I will coat the stock with a thin layer of dyna glass, will sand it smooth, create some wood grain with a rasp and then paint with a thick coat of ocrhe acrylic, over spry with walnut wood stain and finally over spray with a dull coat protective finish. This is what i used on the recruit edition Garands and they presented a very convincing look. The film of dyna glass feels more like wood as well and the end effect of the stain creates a darker, more military stock appearance. I also plan eventually to fill those annoying holes on the sides of the magazines and the bolt holes in the front handguard.

|

|

stuka

Sergeant

The one and only

The one and only

Posts: 1,205

|

Post by stuka on Apr 9, 2013 14:03:52 GMT -5

I want to make it look like the Bakelite but i don't know. How to go about it

|

|

|

|

Post by brownien on Apr 9, 2013 15:05:11 GMT -5

On my Custom BAR, I just sanded it with rough sandpaper and painted several coats of flat black paint. after that you can clear coat it with flat clear coat, and give it a once over when dried with fine sandpaper to give it a used look.

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Apr 9, 2013 15:10:58 GMT -5

Brownien is spot on. The BAR bakelight finish was simply a dull black finish. Any good flat black on the stock plastic would look good. There are paints available that create a blackboard finish and that also should create the look you want. Select a paint specifically created for plastic however which means you may have to do a satin finish that you overspray with dull coat.

|

|

shiftysgarand

Corporal

BangbangbangbangbangbangbangbangPING

BangbangbangbangbangbangbangbangPING

Posts: 1,165

|

Post by shiftysgarand on Apr 9, 2013 18:56:59 GMT -5

I would use model airplane dope, as it is meant for plastic.

|

|

|

|

Post by brownien on Apr 9, 2013 19:19:43 GMT -5

Model airplane dope? Never heard of using that before. That could work, I've only used it on covering models with tissue. though.

|

|

stuka

Sergeant

The one and only

The one and only

Posts: 1,205

|

Post by stuka on Apr 10, 2013 20:47:11 GMT -5

when i fix my bar i'll pry try that or something thanks

|

|

shiftysgarand

Corporal

BangbangbangbangbangbangbangbangPING

BangbangbangbangbangbangbangbangPING

Posts: 1,165

|

Post by shiftysgarand on Apr 11, 2013 16:19:02 GMT -5

I'd use Testors, they're really good.

|

|