|

|

Post by killbucket on Mar 26, 2007 10:48:09 GMT -5

Yes, it has a mean drop to the trajectory. Buckings are about impossible to find for it.

Incidentally, use talcum powder to install new buckings, not silicone spray. Improves success rate 10x.

Thank you all for the momentum burst I am feeling. My new MP40 is on its way to me! (I'm avoiding learning about this model's history for now. I'm taking it apart the minute it arrives, don't need any emotional attachment...)

M249 gearbox sounds more and more feasible. I like what you are telling me about it. Any knowledge of pics of similar work done with this unit? I'd love to see what other wrenches have done with it, not just in .30's... a pic of a gearbox, side on with an item of known size next to it, would tell me a great deal about what kind of design challenge this will be.

My ver2 Marui 733 box has seen over 25.000 rounds at 9.6v, using a 170% spring and every other internal upgrade available, except torque-up gears. It has the stock 1000 motor. Hasn't broke...yet.

|

|

DeB

Private

AGM MP40 - Marui M733 and G3A4 Revenant

Posts: 179

|

Post by DeB on Mar 26, 2007 11:31:35 GMT -5

My ver2 Marui 733 box has seen over 25.000 rounds at 9.6v, using a 170% spring and every other internal upgrade available, except torque-up gears. It has the stock 1000 motor. Hasn't broke...yet. Lucky! But maybe I have shot some more bbs... and in bursts of hundreds and hundreds.... I have a 2500 bbs box mag  |

|

|

|

Post by mikkel on Mar 26, 2007 11:58:14 GMT -5

The M249 box has the disadvantage that it is open at the bottom the unit. Exposing the gears. This would require the box to be mounted in such a way, so the gears do not have contact with anything. The MP40 box on the other hand, is fully enclosed, and will be easier to fit inside the gun.

Another problem with the M249 box, is that the trigger mech, is located at the bottm of the unit, requireing the actual trigger to be directly below the gearbox. Unless the electrical unit is relocated to somewhere else.

What would the price for a complete unit (minus gearbox of course) with tripod and shipping to Europe be?

|

|

|

|

Post by applestrudel on Mar 26, 2007 20:11:40 GMT -5

Do the airsharp plans include directions on building a feed assembly or a mag well?

|

|

|

|

Post by killbucket on Mar 26, 2007 22:13:11 GMT -5

Depends what country. Import/gun/fake gun laws vary by region, Let me know where you are talking about. To Sweden from California, Roughly $100US, I would pay half, as shipping costs within the US are factored into pricing. So, $345. I will complete the tripod I'm working on this week, for now the ammo feed is up to the builder. My plan set has a 3/8" diameter x 1/2" deep hole under the ammo feed tube at the gearbox nozzle.   The spring: www2.acehardwareoutlet.com/(yxbted45ngd0ynrbcd3ndcmi)/productDetails.aspx?SKU=5214069This is a 3", they also have 5" available, this is what I used, just not finding it online. You may or may not need superglue for the shink unions to the plastic tubing. The ammo feed tubing can be short sections of a cheap mag loading tube or any 1/4" i.d x .375" plastic tube. In time, I will design a substructure to go into an ammo can and mount to hold the feed setup. I'm leaning more towards an AK Hicap, off-the-shelf stock. The motorized feed will be a minor hurdle. Everything mechanical should use "donor" tech. Tamiya makes little "educational kit" gearboxes that are compact. The AK mag I have here has one of those wind-up keys, so the drive hex/hole is already there. Why re-invent the "whole wheel"? FeedSpeed (registered trademark?) will be tricky to get right, I think. Some fuzzy math involved, I just know it... That 249 part is not down for the count yet. But buying a bare gearbox, then the gears...um, what about all those little bits? This is why street rodders use donor vehicles. And why I still advocate starting with a complete engineered system, and moving it to a new shell. It saves time and experimentation. That being said, if you are a SawMan, you may find something to like in an "antique Saw", and I will design mounts for those guns, in time. Anybody with a dead, broken, or otherwise orphaned/broken gearbox shell of this type, my address is on my site. This process would take place a lot sooner with a guinea pig to mike. I don't dare buy (and dissassemble, yikes!) a whole Minimi. I know it would become a distraction in itself. Still avoiding learning WHO the MP40 is. She goes under the lamp and tools as soon as she hits the doorstep. |

|

biged

Master sergeant

Posts: 468

|

Post by biged on Mar 27, 2007 5:30:02 GMT -5

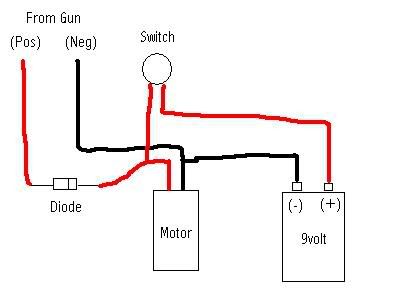

I made this a couple years ago for my M60.  This runs off the power of the gun. I have a primer switch so the gun does not dry fire 20 times before the first bb reaches the hopup. It's the same spring you described (connected with 5/16 ID clear poly tubing) to the internals of an M16 mag. A splined connecting plate is epoxied to the the side of the winding wheel of the mag. A Futaba S148 servo connects to the plate. A primer switch, diode, and tamiya connector from the gun.  There is a screw hole in the lower left hand corner of the M16 which lines up perfectly with a mounting hole in the radio shack project box. I cut the tin plate that came with the project box and used it as a deck to keep bb from falling into the mag area. The box has slot rails cut into it so the tin plate does not move. The whole mag cost: Futaba $25 Project box $8.00 Switch $3 Diode (2-pack) $1.00 9v battery $3.00 9v Connector (3-pack) $4.00 Epoxy $5.00 Shrink wrap $3.00 Wire 16 gauge (3-pack, red,black, green) $10.00 M16 hicap guts Free. (We got 40 or 50 broken mags, I replaced the clock-spring inside.) It does take 4-5 to put ONE togather. You have to mod the servo to make it rotate 360 degrees. It may be easier to buy an SAW box mag and rip out the feed system. The newer ones are only 4"W x 5"L x 5"H. They are bottom feeders not top feeders like my setup. FeedingSide Note: That feed spring fits directly into the opening of a hicap and the bb catch holds it in place. Works great for testing. I now unwind the spring using vise-grips and insert 5/16th ID brass hobby tubing. Here is a older pic of the spring with clear poly connector.  You have to run the poly tubing under hot water to get it over the brass or the spring. The lexan feed elboe are for Top M60's, this way you can see BB's feed.  I made a bunch of them. I may sell a Bolt On conversion kit for Top M60's to convert them to a V3 box. Something that is not pictured is how you load the mag. I used a peanut butter jar lid...  I cut the rim off so it was just a plastic round disk. Drilled a hole in the center of the lid and another hole on the top of the mag. I then put a 5/32 bolt through both holes and double nutted the bolt so it won't spin off. Then I drilled a large .5" hole in the lid and the mag. Now you just spin the lid to the line up the holes and pour in BB's. (I'll post a pic tomorrow.) I've made alot of box and exotic mags.     ///ed/// |

|

|

|

Post by mikkel on Mar 27, 2007 6:35:38 GMT -5

I have also gathered up my skillz in paint  What i imagined that the design would be:  I am very confident that all the components can fit inside the shell of the 1919, as it did in Schmittys design. |

|

|

|

Post by killbucket on Mar 27, 2007 10:23:16 GMT -5

I like what I'm seeing. The servo is a brainstroke. I love designs using bits of other things. What rate of fire are you able to support with this device, by the way? Could you post instructions on the servo mod? I've seen this done before but not sure how to go about it. The tripod is coming along.  As I've stated previously, it will not be a replica, it will be a smaller version resembling the original in some details. The main body will have a very close resemblence to an original, but the legs will be shorter, and will not telescope to fold. Anyone wanting something more realistic or with the ability to hold a real LMG should seek one of the many people pursing that in metals. My design will be suitable for AirSoft or Static display, and be reasonably cost-effective. As far as everything being self-contained, what you are looking for I think is an A6, so it can be lugged around, Arnold-style. I know of work that is being done, but am not at liberty to give much detail, other than they will be m249-class priced, and be all metal. Watch the marketplace, it is not my company who will announce this. I'm sticking to polymers, by the way, to stay with a reasonably-priced product. I have no problem being considered the "cheap" 1919 guy. The LPEG-based 1919A4 with the minigun grip shown earlier in the post had a gravity-feed hopper inside it, and acted like it. Make up a cardboard replica of the inner dim's given earlier. Put a mag inside. Space starts going away. Add the workings...I like your idea of running the barrel thru the ammo bin, but realistically, the hopup takes space, needs to be adjustable, etc. Not saying it can't be done, just would take an intense development cycle. Keep in mind it has to be repeatable in mass qty's! Maybe a better option would be using a more compact ammo can? They were out there. Another option would be inside a canvas shellcatcher. The Brownings eject from the bottom, it wouldn't look out of place. You could then just use an m4 mag, no hosing required. Or something I just found online: www.bhigear.com/index.asp?PageAction=VIEWPROD&ProdID=3233They have a PKM I really want to make a conversion kit based on...this is for later. |

|

|

|

Post by Tough Ombre on Mar 27, 2007 11:55:39 GMT -5

For my gun i planned on making an external ammo bin w/ a servo motor. Located in a 30 cal ammo box. It be a hicap in the ammo box w/ an expanded hopper. Then wire the motor as follows. Positive wire -straight to motor Negative wire- Splits in two, 1 goes to trigger system and then to the servo. Other wire goes to a switch that is operated by pulling the bolt back Then it goes to the servo. Then i planned on using flexible tubing under an ammo belt to go from the hi-cap too the Gun from there it would have a removable clip that clips on to hard brass tubing, that the feeds it into the gun. The way that it is wired allows for A: you pull the bolt back on the gun and it starts the servo which "primes" the gun ( feeds the ammo all the way into the gun) Then B: after its primed you pull trigger, this fires the gun obviously but also will start the motor, thus giving you and endless supply of ammo. The battery will also be contained in the ammo box. The motor i plan on using is from an LPEG i bought years ago. It will be run by a 7.6 volt rechargeable bat.. as to not drain the battery for the gun. the wiring for the switches will also be run under the belt of ammo w/ the feed tube. That will go to points in the belt feed on the gun where it will "plug" into the internal wiring in the case for the switches and such. that way you can remove it and stay on the move with the gun. and you wont be able to operate it w/o the belt and box. Now.. i just gotta make the case  -Cary |

|

|

|

Post by mikkel on Mar 27, 2007 19:31:03 GMT -5

If i get it right, the legs on the tripod will be able to fold, but not like the real ones do? I'm not quite sure of the specs on the servos, I myself have not used them yet in my own projects. A friend have, and he said that it easily can deliver ammunition to even the most hungry guns. There are many diffrent servos out there, so it's just a matter of finding the right one, one that's fast and powerful enough, but also not very expensive. The one my friend used cost around 10$, but it was purchased in Denmark, so that might be of no help at all. My previous project used the motor from an electric screwdriver, coupled with two household 1,2V AA batteries, it delivered enough drive to easily feed my 1000rpm gun. It was very cheap, the downside was the size. It was at least 3 times the size and weight of a decent servo. So that's the one i'll try next time  The inner barrel would most likely have to be protected by an outer tube- that prevents the bbs from interfering with the barrel, affecting the guns shooting performance. Currently, my design should cost about 40$ to make, all included. If you can sell me a unit cheap, and with the internal frame built to the specs i need, I can promise that i will design an internal magazine solution that will neither be too expensive, nor very hard to replicate, for you to use in following designs  |

|

|

|

Post by killbucket on Mar 27, 2007 19:34:42 GMT -5

Absolutely brainy. Great use of the bolt to set the mag up! I like it! It makes perfect sense to do that. I saw the Thompson animated-bolt mod last night...choices, choices. Maybe both could be combined somehow.

That Schmitty is a Wizard. I am in awe of the engineering. He probably already has the answer to this....

|

|

|

|

Post by Tough Ombre on Mar 27, 2007 20:48:16 GMT -5

Lol... he used and internal hopper. Thanks, i have everything planned out... just got to get the materials.. and cut them out.. straight lol. Also i was thinking that how to make the bolt so it comes back is to attach and LPEG gearbox too it some how. though the only prob with that is having to sychronize it. Though im sure it can be done.. some how lol. I will try to come up with something.

-Cary

|

|

biged

Master sergeant

Posts: 468

|

Post by biged on Mar 28, 2007 4:24:23 GMT -5

Mikkel,

Laying a hicap down on it's side will not feed properly. It will feed intermittantly. It's been tried many times before over the years with mixed results. I would suggest testing & experiementing with it first before assembling eveything. Even a agitator/vibrator from a cell phone or a game controller has been tried, again with mixed results. The shorter the hi-cap internals the better if space is needed. MP5 hicap internals are shorter than M16 internals.

Killbucket,

I will take some pictures and post a link on how-to modify a servo to spin 360 degrees. Takes about 30 minutes. Once you have done one, it will take < 10 minutes after that. They only spin 90 degrees out of the box because they are used in just about every RC car, Plane, and Robot on the market. Builders like them because they are lightweight, high-torque and have bearings. They feed a from a hicap a healthy 28 rounds-per-second on a 9v system. I heard they can run up to 32 RPS with a 10.8v. Any more voltage than 12v and they will meltdown.

The feed limit of mags (hi-cap or standard) is 30-35 rounds per second. After that you need an air-feed system.

///ed///

|

|

|

|

Post by mikkel on Mar 28, 2007 4:50:15 GMT -5

biged> Are you so sure? I'm sure the MAG 100 round M249 magazine us this method? I'll get my friend to open up his, so i can find out  It utilizes a very compact and stabile design, with a 2500bb capacity. The spare space inside the browning should be at least the same? ` Even is this system fails, i have plenty other ideas as how to maximise the bb capacity while maintaining the internal mounted system  If i could get some measurements off the internal dimensions of the reciver, i could make some more accurate drawings? |

|

|

|

Post by killbucket on Mar 28, 2007 10:55:02 GMT -5

14.25long x 1.5 wide x 3-7/8" high. The MP40 is to arrive UPS today. Tools ready! The dual-plate mounting for the internals uses up too much space. I'm going to do up a new design, hopefully with mounts for all three gearboxes mentioned. What the hell, I'll pull out the WellD90 layout and include that also. I'm planning to mount my mag at an angle:  this will allow the area in the white box to become a bb hopper. This motor should be big enough to turn the mag wheel directly, but this has not been tested yet... |

|

|

|

Post by killbucket on Mar 28, 2007 22:30:51 GMT -5

MP40 in hand. While the world sleeps, I will gut this poor innocent in the name of progress. I just realized I am killing a German to help an American...Mr. Browning would approve, I hope.

This thing is nice! Now do I turn the housing into a dummy (fill with water putty, intense antique job) or sell it? The battery it came with is very bitty. For a completely internal setup, I will try to include it in the design criteria. But don't count on ME actually using one of these...I want sustained firepower.

|

|

|

|

Post by killbucket on Mar 29, 2007 0:04:16 GMT -5

Mikkel,

We've got to get you over this ammo can phobia. Are you wanting an A6, with shoulder stock and such? Otherwise, a real Browning needs an ammo can of some kind. I suppose 600 or so rounds could be worked in, but I want more than that on tap...SUSTAINED fire.

I invite you to design and market your own system. As an ammo feed is not included in a complete gun (outer shell, standard airsoft mount, tripod), this would not affect pricing at this time. When it is developed, my system will be available separately as a drop-in .30 cal ammo can conversion. This will allow those like yourself to set up what they prefer, instead of being stuck paying something you aren't going to use. My plans sets include everything designed for the gun.

This is where the 30cal doesn't quite translate to AirSoft. We are used to carting our gats about, firing at will. An LMG is a "camper" weapon, it needs a placement. A real one weighs over 30 pounds. AirSoft is a battleSport. So far. Get ready to meet more like myself, gun enthusiast...er...nuts who like real guns, but are fed up with the ever increasing limitations on their ownership/usage. I don't own a single one. I grew up with all kinds of them in the house (rural Washington State), and was completely bored with them. So many years later I am bored with RC Cars...but I digress...

I consider my Browning to be a recreational gun more than a combat weapon. (I'm going to set one up on my mother-in-laws' backyard table for squirrel control. It probably won't kill them like her .410 shotgun does. She's not quite comfortable axing them, just wants them out of the walnut trees.) I don't really think that many of my guns will see battle. Most examples so far have been ordered with the intention of static display. I am selling primarily a cost-effective 1919A4 HB copy in ABS. The AirSoft conversion idea came second, and for my own enjoyment. I enjoy a technical challenge.

I have a target area setup in my yard, and still haven't gotten bored with cutting paper targets to bits. Nice to sit back in a lawn chair, casually ripping up whatever, gun comfortably mounted on a swivel.

The Browning is BIG (My upcoming M2 gun is HUGE). I think adding bulk (tripod,ammo can, link chute, aircraft sights, liquid-cooled barrel, personnel shield, even sandbags, etc.) only ADDS to the realism. This isn't a gun you toss in the truck and go show about. This is something you display with all your other gun swag, and only let "lucky" people at it. A centerpiece. I love telling houseguests, "yes, those really fire". Even people who are "against guns" have subliminally seen too many movie war heroes at the controls, and in spite of themselves, ask questions (I have their fingerprints on a gun, too, if they act up later).

Notes: The lid on my gun flips up correctly. The tripod head will be about actual size/shape. The legs will be shorter, and will fold as on the actual units. The transit bar will be a simple crosspiece, pinned into place. Krylon (preferred is black texture) and Rustoleum make paint for plastics, yay! At least use this for a base coat. ABS is tricky stuff to paint. Or it used to be. Bondo works great for molding, sand surfaces with 320 beforehand.

|

|

|

|

Post by killbucket on Mar 29, 2007 3:35:45 GMT -5

The MP40 is apart. The components will fit much more easily than I had hoped! I am tempted to set up for a Marui-style hopup and barrel, but I will leave that for the REAL customizers. A simple bracket will be all that is needed to mount up the electrical and mechs from the MP.

Skip Ver2. This will be a pure Version3 design, and look very authentic.

BigEd-great suggestion.

Tommygunner -THANK YOU for starting this thread!

Mikkel - It looks like you were right about space, but you will still have to do jet-fighter component packaging.

For the ammo feed, the best solution looks like a flex spring as mentioned earlier. I will devise a way to route a string of hidden bb's from the ammo tin.

Side notes: Many loose screws inside the MP. Two extra lockwashers floating in the bottom of the handle. Gearcase has hammer/grind marks all over exterior. 1 motor mount screw is stripped. The pinion-depth adjusting screw is not present, but mesh sounds ok.

This gearcase would work for a lot of other guns, however. MUCH cheaper than an M14 or a M249. And now my Browning will have a $150 "total rebuild kit".

|

|

|

|

Post by mikkel on Mar 29, 2007 5:51:56 GMT -5

Good to hear that the project is progressing! I'm actually lookign at two different set-ups right now: One that will be mounted on a veichle (Willeys Jeep) with ammunition can and all that. And the other that's going to be man portable and have to have everything inside. I really like to tinker with those projects, so i'm looking forward to have a go at the ammunition "problem"  I also love the thought of having to open the lid after the initicla ammunition have been spent. and have to reload that way  I'm looking forward to see pictures of the progress! |

|

TommyGunner

Staff Sgt.

Hackjob Mauro

1st Marine Division, 1942

Hackjob Mauro

1st Marine Division, 1942

Posts: 2,265

|

Post by TommyGunner on Mar 29, 2007 9:06:27 GMT -5

Looks like everythig here is really progressing, glad to see this is all happening, I plan on starting my 30cal in the next month or so.

TommyGunner

|

|

|

|

Post by killbucket on Mar 29, 2007 11:01:25 GMT -5

I may not sleep for a few days....This is going to be SO easy. Anybody other than me think we could use more barrel?  The way the trigger operates fits right into my evil plans. If this goes as smoothly as I think, the cost of my product just went down. Everybody wins. The MP40 sans motor/gearcase, barrel/hopup, and wiring, is available to the highest bidder, I'll pay shipping in the US, 1/2 to elsewhere. The bitty battery and charger, all other box contents included. NEVER fired...ha! |

|

|

|

Post by mikkel on Mar 29, 2007 12:39:52 GMT -5

I'm actually interested in the MP40 shell. My current one can also use another battery  Maybe we can work something out, if/when i purchase the 1919(s) ? The hop and barrel in the MP40 is not the best in the world, so I would suggest you to exchange it for a AK type hop-up and much longer inner barrel (591mm perhaps). Thats what I'll do anyway  I'm really looking forward to see how it will end up  |

|

TommyGunner

Staff Sgt.

Hackjob Mauro

1st Marine Division, 1942

Hackjob Mauro

1st Marine Division, 1942

Posts: 2,265

|

Post by TommyGunner on Mar 29, 2007 13:53:10 GMT -5

So killbucket your going to sell these, while Im going to be attempting my own I would be quite interested in purchasing a 30cal from you.

Or possibly trading something and adding cash as needed?

TommyGunner

|

|

|

|

Post by applestrudel on Mar 29, 2007 19:26:25 GMT -5

TO conceale the bb tube you could buy some dummy rounds and a belt and drill holes through the rounds for the feed tube to go through.

|

|

|

|

Post by killbucket on Mar 29, 2007 20:10:54 GMT -5

I'm sticking with using the complete MP 40 system. (The streetrod donor vehicle thinking, here) I don't want to ask my customers to search for odd bits they may not already have, or have to disable/cannibalize two different guns.

The MP40 is a perfect fit otherwise. It's performance is acceptable, yes, it could use more range. It seems that only after much use, are people needing to address hopup problems. The way I design things, it will be no big deal to put in a AK hop or something like that. The problem will be making it work with this gearbox. I understand (per Schmitty-posts) they are not easily compatible. A simple way of extending the barrel may have more merit. I like the idea of a complete, everything new mech setup for ~$150.

I want to liquidate the MP40 shell/box contents as an isolated deal. I have no idea what their value should be, so the fair thing to do is call for bids. The winner will get a private message outlining purchase details. I will announce the close of bids to all involved. Basically, I will put this into the shopcart with a single qty. The winner may then use any of the four major credit cards for easy payment. The box will be shipped Priority Mail. This will take four days or less for delivery, in the continental US from Calif.

TommyG:

Although I am, as policy, not interested in trade-ins, here's my personal wish list, guns I do not own.

Metal Broomhandle Mauser Pistol (gas)

Mac 10 or 11 full Metal body (gas)

SOCOM Mk23 (GAS)

Dragunov (AEG)

PSG-1 (AEG)

M14 wood stock (AEG)

(PS. Anybody having all these already, ....I hate you. Just so ya know. It's not personal.)

Six, possibly seven things there...I really expected to list more items. Well, I also want a Toytec Minigun, who wouldn't?

Also on my sickness list:

Tamiya Clodbuster

Tamiya Wild Willy2

|

|

|

|

Post by Tough Ombre on Mar 29, 2007 20:12:23 GMT -5

My plan was to run the tube either through the rounds, or paint it white and run it under a cloth belt. If i get a cloth belt i will probably run it under it, and if i get a link belt, i will drill holes in the rouns. the only thing about that is there is more of a possibility of the tubing getting crimped by the wieght of the links pulling down on it. I think that running it under would be the best answer, allowing for you to A see it and make sure its feeding correctly, and B it would keep it from crimping , and i think i am just repeating myself lol. but you got the idea.

-Cary

|

|

|

|

Post by killbucket on Mar 29, 2007 20:20:47 GMT -5

For Now I'm stuck with live rounds...I have a specialist "demilling" some for me. I already have several links (incidentally, you can buy as many links as you wish in CA., but can only legally put ten or less together in any given string, that would be a "hi capacity magazine") to use for the photo sessions. at the very least, once my ammo tube is set in place, I will heat shrink it, thereby freezing it in shape and turning it flat black. I will hide it somehow.

I cannot find pics of the shadow I am standing in. Namely, Schmitty's A4 or A6 I find mention of...

Ok, I'm off to the CAD system for a while...

|

|

|

|

Post by Tough Ombre on Mar 29, 2007 21:07:59 GMT -5

he just sold it on ebay.

-Cary

|

|

|

|

Post by killbucket on Mar 29, 2007 22:43:34 GMT -5

I know, I had seen those posts, I was hoping for an old pic or two from the build process. Meanwhile, enjoy:  Double-check your dimensions, the parts themselves are sure to vary a bit. |

|

|

|

Post by applestrudel on Mar 30, 2007 19:14:36 GMT -5

How do you plan to hook the servo up to the high cap? would soldering work?

|

|