|

|

Post by droopaille on Sept 30, 2013 15:01:12 GMT -5

First there are the pics, i will comments a bit soon The goal  Acad plans droopaille.free.fr/Airsoft/M2/Browning M2.dwg ![]() First cardboard model Not the goog ammobox but i have nothing else  Cut in 1.5mm steel plate. White lines are the groove for the folds  Folding are made with a simple vice.  The first blank assembly. It makes 60cm long.  Pre cut of handles.  Different sizes of steel tubes for barrels  Find on FranceAirsoft, a paintballer who bought the external part and sold the inside In this case of luck, in french we say : "i have the ass bordered with noodles"  First try for the holes, very difficult, my drill is turning too fast.  The solution was a hole saw.  |

|

|

|

Post by aj czarkowski on Sept 30, 2013 20:04:41 GMT -5

"I have the ass bordered with noodles"!? Not exactly sure what that means, but the project is looking good so far  |

|

|

|

Post by droopaille on Oct 1, 2013 12:12:22 GMT -5

lol may be we can also say : "get his ass lined with noodles"

french literal transaltion ...

it means that i was very lucky to find there parts

|

|

|

|

Post by droopaille on Oct 6, 2013 4:19:41 GMT -5

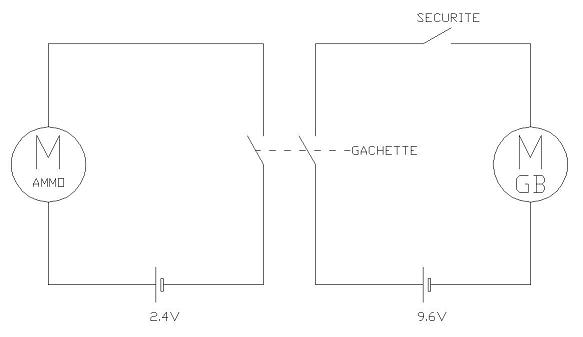

I add comments in the first post. And the rest. The trigger. I think i have made harder than necessary. Trigger push a double contactor : one for the gearbox and an other for the amobox    Front and rear plate in 5mm steel.  Finish of handles  Just for plasure of eyes.    |

|

|

|

Post by droopaille on Oct 6, 2013 4:31:30 GMT -5

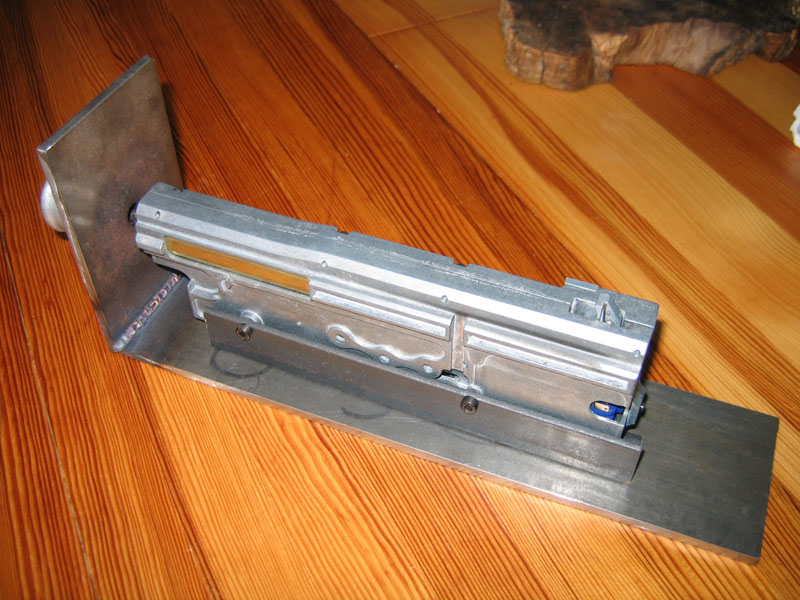

Drilling and taping of rear plate.  The wood part of handles.  And far time later, i made them round : it is nicely.  [/quote] The trigger is finished.  Different parts of barrels : - front plate - airsoft barrel with hopup bloc - barrel (750mm) - barrel guide - heat shield  |

|

HornetWSO

Private 1st Class

"We may not have a history, but we have a rendezvous with destiny!"

"We may not have a history, but we have a rendezvous with destiny!"

Posts: 551

|

Post by HornetWSO on Oct 6, 2013 10:54:15 GMT -5

Incredible detail, impressive design, fantastic quality of your part fabrication. I'm quite excited to see this progress!! Keep it up!!

|

|

shiftysgarand

Corporal

BangbangbangbangbangbangbangbangPING

BangbangbangbangbangbangbangbangPING

Posts: 1,165

|

Post by shiftysgarand on Oct 6, 2013 13:24:28 GMT -5

I like the steel construction.

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Oct 7, 2013 1:17:35 GMT -5

Tres Manifique!

|

|

|

|

Post by droopaille on Oct 7, 2013 16:08:40 GMT -5

Thank you

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Oct 8, 2013 2:20:02 GMT -5

Without good tools, cutting and drilling metal is so difficult and time consuming. I have a .50 cal (not metal) so i will be curious to see how you do the internals and the feed system. In a perfect world it would be shooting 8mms and would be set up at extremely high power for angled plunging fire but automatically de tune when aimed directly so you'd have exceptional range but built in safety.

BIG ED built a spectacular .50 Cal way back when(all metal) that was pneumatic

|

|

|

|

Post by tango on Oct 8, 2013 15:46:30 GMT -5

Fantastic work, looking forward to more updates! In a perfect world it would be shooting 8mms and would be set up at extremely high power for angled plunging fire but automatically de tune when aimed directly so you'd have exceptional range but built in safety. That is a really interesting idea. |

|

shiftysgarand

Corporal

BangbangbangbangbangbangbangbangPING

BangbangbangbangbangbangbangbangPING

Posts: 1,165

|

Post by shiftysgarand on Oct 8, 2013 16:48:52 GMT -5

PPP(Piper's Precision Products) makes a $3000 GBB 8mm Browning M2HB, which is unbelievably awesome, but unbelievably expensive.

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Oct 9, 2013 2:25:29 GMT -5

It is no doubt a reflection of what it truly cost to make these if the intent is to sell them commercially people who have never taken on projects such as this haven't a clue how much time and effort they require.

The pipers PrecisionProduct is internally a fairly straight forward gas system that work quite well. It is a version of a design the Army once used During WW2 for aircraft gunnery using steel BBs. they were called McClashin devices and they forced high pressure compressed air into a reservoir of BBs which had a funnel that tapered into the barrel. A trigger allowed the pressurized air into the bb box. The Bbs were aggitaded by the air and were forced out the barrel at an incredible rate of fire. Power depended on the pressure applied but these guns were capable of tearing through garbage cans at a high enough PSI.

Gunners in bombers were trained Using them as it saved ammo and allowed training on the ground that wouldn't require the space or safety measures an actual .50 cal would require. The old trainer guns come up for sale from time to time and like a lot of things used to sell pretty cheaply.

BIG Eds .50 Cal functioned the same way and is a real hog for air but is extremely impressive both to look at and fire. My .50 cal is an AEG with a M249 gear box and box magazine it is mounted in my Jeep

|

|

|

|

Post by droopaille on Oct 10, 2013 11:43:57 GMT -5

The system you discribe with high pressure chamber is known as cloud BBMG or more efficiency a vortex BBMG (you can easy find and make one for few money). I don't know how you play but in France all teams accept the same conditions : full auto less than 350fps (0.2g), semi auto less than 400fps, and bolt less 450fps (legacy is under 2J for airsoft gun). For my machine gun, i have to choises : less power but hight rate or high power and low rate. I had choosen the first one (350 fps with 9.6V power) but it had be more realistic to choose the second (400 fps with 7.2V power). In my team all people play in semi auto except support gun and with the capacity of amobox, using the machine gun is a real advantage versus other players. When i buit the .50 i hadn't my milling machine and my lathe, only a column drill, a grinders and access to a welding post in my job. THe solution is very simple for the inside. If you can't wait the translate, you can find the french tutorial and all of other mine here droopaille.forumgratuit.org/t2-browning-m2-50 |

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Oct 11, 2013 1:07:33 GMT -5

The cloud vortex is a great approach but impossible to consistently use so that it stay within the fields FPS limitations. Too many variables that can go wrong. The French limits are very similar to the field FPS set up over here. i love that most of your players are limited to semi and you only allow box mags on the crew served weapons.

|

|

|

|

Post by droopaille on Oct 27, 2013 5:37:41 GMT -5

the gearbox is fixed with a simple steel bracket and 2 screw  With the same steel, the bow support   And welded    Good job ! (TIG welding)  This parts for in inner ammobox with 4mm polycarbonat, just cut with a hand saw and a ruler   I add the inner part of M249 ammobox  The space reamining is for battery  Near the finish Empty  Full  Little game : how many bbs at your mind ? |

|

HornetWSO

Private 1st Class

"We may not have a history, but we have a rendezvous with destiny!"

"We may not have a history, but we have a rendezvous with destiny!"

Posts: 551

|

Post by HornetWSO on Oct 29, 2013 23:00:57 GMT -5

6000

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Oct 30, 2013 10:16:39 GMT -5

You are getting excitedly close to finishing. It all looks terrific. Huge effort for a really cool project. Thanks for sharing. Looks like 4872 round magazine to me.

|

|

|

|

Post by droopaille on Oct 30, 2013 14:18:08 GMT -5

The M2 is an old project finished since few years, and recently dissassembly for monting the cal.30.

Box contain a bit more : 10000 bbs (yeah it's a bit long to firing all of them) lol

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Oct 30, 2013 17:13:31 GMT -5

wow. 10,000 ready rounds. Serious battery required!!!!!!!

|

|

shiftysgarand

Corporal

BangbangbangbangbangbangbangbangPING

BangbangbangbangbangbangbangbangPING

Posts: 1,165

|

Post by shiftysgarand on Oct 30, 2013 17:28:29 GMT -5

He needs what, a 6000 mah battery?

|

|

|

|

Post by droopaille on Dec 1, 2013 8:09:42 GMT -5

Electrical supplier from M249 ammobox  inside the box  electrical plan : one push, two action (fire and supply)  In real, it is a bit less sexy  The front plate very barrel support   |

|

|

|

Post by droopaille on Dec 1, 2013 8:14:47 GMT -5

|

|

|

|

Post by Flippy on Dec 7, 2013 5:04:12 GMT -5

Hmmm... Really nice!!! Only thing I don't like, is it's weight...  -How many cm is that ammo box inside (cm×cm×cm, or inch if you want...)? I mean the part which contains the 10000 BB... I'm asking because I'm thinking about my MG15's capacity. -What kind off tubing do you use to guide the BBs (I mean what's the original function of that tubing)? Thanx: F. |

|

HornetWSO

Private 1st Class

"We may not have a history, but we have a rendezvous with destiny!"

"We may not have a history, but we have a rendezvous with destiny!"

Posts: 551

|

Post by HornetWSO on Dec 7, 2013 19:42:22 GMT -5

Droop, You make it look so easy and common sense, the mark a true craftman!

|

|

|

|

Post by droopaille on Dec 14, 2013 6:26:04 GMT -5

Many thanks but i'm not an magician, just a patient and stickler guy.

the tube is the spring of the amobox, there is 2 springs on M249, one for bbs and an other for the microphone wires (for sound control auto run)

twice are the same and they can be mounted end to end for more lenght

ID is 7mm

i'm looking for a supplier for buying some by meter for my .30, i know someone who had bought one but i don't know where

for the case, 195*135 and the bottom is an inclined plane

|

|

|

|

Post by droopaille on Feb 3, 2014 13:08:12 GMT -5

Rest and end of this project. In fact, i haven't finished the machine gun. It is usable but there is no finishes, no paint ... folding the cover hinge   The end of welding support.  Fixed the kneecap with a salvage part of pneumatic cylinder.  Holes for cables and spring loader  nearly the end !!  www.youtube.com/v/m3fFXVWGGRs www.youtube.com/v/m3fFXVWGGRs16.2 kg - 1m45 of steel for outing everybody : you shall not pass !!!!!!! This is a tripod for having fun quickly but not cute  the heat shieldIt miss the maiden  In modern situations   |

|

shiftysgarand

Corporal

BangbangbangbangbangbangbangbangPING

BangbangbangbangbangbangbangbangPING

Posts: 1,165

|

Post by shiftysgarand on Feb 3, 2014 15:28:48 GMT -5

Looks awesome! Tres bien!

|

|

|

|

Post by droopaille on Feb 4, 2014 14:06:58 GMT -5

Thank you

|

|