|

|

Post by hardslack on Apr 21, 2015 9:30:41 GMT -5

From looking at that sketchup file, you would need a big printer to print it all in one piece, most are not that long. And most have low resolution, so the part would need to be sanded everywhere or it would be really bumpy.

|

|

|

|

Post by insterburger on May 2, 2015 18:02:56 GMT -5

I did the initial cuts on the stock, and I think it will work. They are some of the ugliest cuts I've ever done, turning 45 degrees didn't help that, but there will be so much fill and buildup that it really doesn't matter.

Setting the two pieces together properly will be a challenge, but I have a plan. The first thing I need to do is have the receiver and barrel at least faked together so that the angles will all be right. The cut on the M14 stock is just ahead of the magwell-- maybe slightly too close-- so I need to be careful not to get too much epoxy inside there. The good news is that there are little hollowed out sections on either side of the magazine-- I plan to put heavy pins in these-- maybe cut down threaded bolts-- let them set, then insert those into holes I'll drill in the 98k forestock. The G43 upper band has already been fitted, so by putting the barrel through that and having all the other pieces in place, I should be able to set the forestock so that everything is where it's supposed to be.

Then the problem will be the width of the two pieces. The 98 stock is wider, but that actually gives me an opportunity to improve the contours on the M14 stock: By building out the side walls, I can make the transitions from the sides to the bottom less square and abrupt. Pictures of all this (hopefully) will follow as I do the actual work.

BTW, is anyone (like maybe 2nd Bat) intimately acquainted with how the receiver pieces fit together? I know I will have to do some cutting, but if possible I'd like to cut AHEAD of where the handguard covers the part that looks like the barrel base. The problem seems to be that the rearmost set of screws that holds the upper and lower halves of that part go through the actual airsoft receiver/gearbox-- and then screw into the part that is the fake M14 receiver. Going into the gearbox assembly is vital, as it aligns the barrel and forward pieces with the gearbox. But is it necessary that it screw into the dummy receiver? The forward two sets of screws seem to hold all that together just fine, and it doesn't seem like any of these parts impact the actual airsoft hopup and nozzle, which are contained within them. I guess my question is, could I make a clean cut just ahead of the exposed part of the M14 receiver and just hold the screws in place with nuts?

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on May 2, 2015 19:36:12 GMT -5

Whenever possible I am a fan of leaving unexposed, connecting parts unalterred and intact as it insures everything remains aligned and intact. For my 30 CALs which used the M14 internals I managed to build them without using any of the M14 receiver group parts but had better durability and functionality when I did. Your thougts about the uneven thickness of the two married stocks is valid if the difference isn't too extreme.

|

|

|

|

Post by insterburger on May 2, 2015 22:15:01 GMT -5

I took another look, and I think I answered my own question: The top front of the M14 receiver isn't 100% necessary, but the "posts" that the screws thread into help form a bit of a backstop for the barrel fairing ahead of it. It appears that the gun would function normally anyway, but it's one more level of alignment that will be worth keeping. All it means is a slightly more challenging dummy M14 build, which to me is a self-evident tradeoff against ensuring functionality on my G43 build.

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on May 3, 2015 17:05:37 GMT -5

That would be my recomendation.

|

|

|

|

Post by insterburger on Oct 10, 2015 17:59:20 GMT -5

After a long layoff I started messing with this again. I've cut the fore-end off the M14 and the 98k, and they are ready to be mated together. The nose cap is present, and I am using the back end of the Dboys barrel I cut off for a 98k build-- there is just enough to work (by cutting the other end just inside the 98k hand guard), and the little notch near the end should be helpful in building up a front sight base when the time comes. It actually looks a lot like the mockup I did in Photoshop:  |

|

|

|

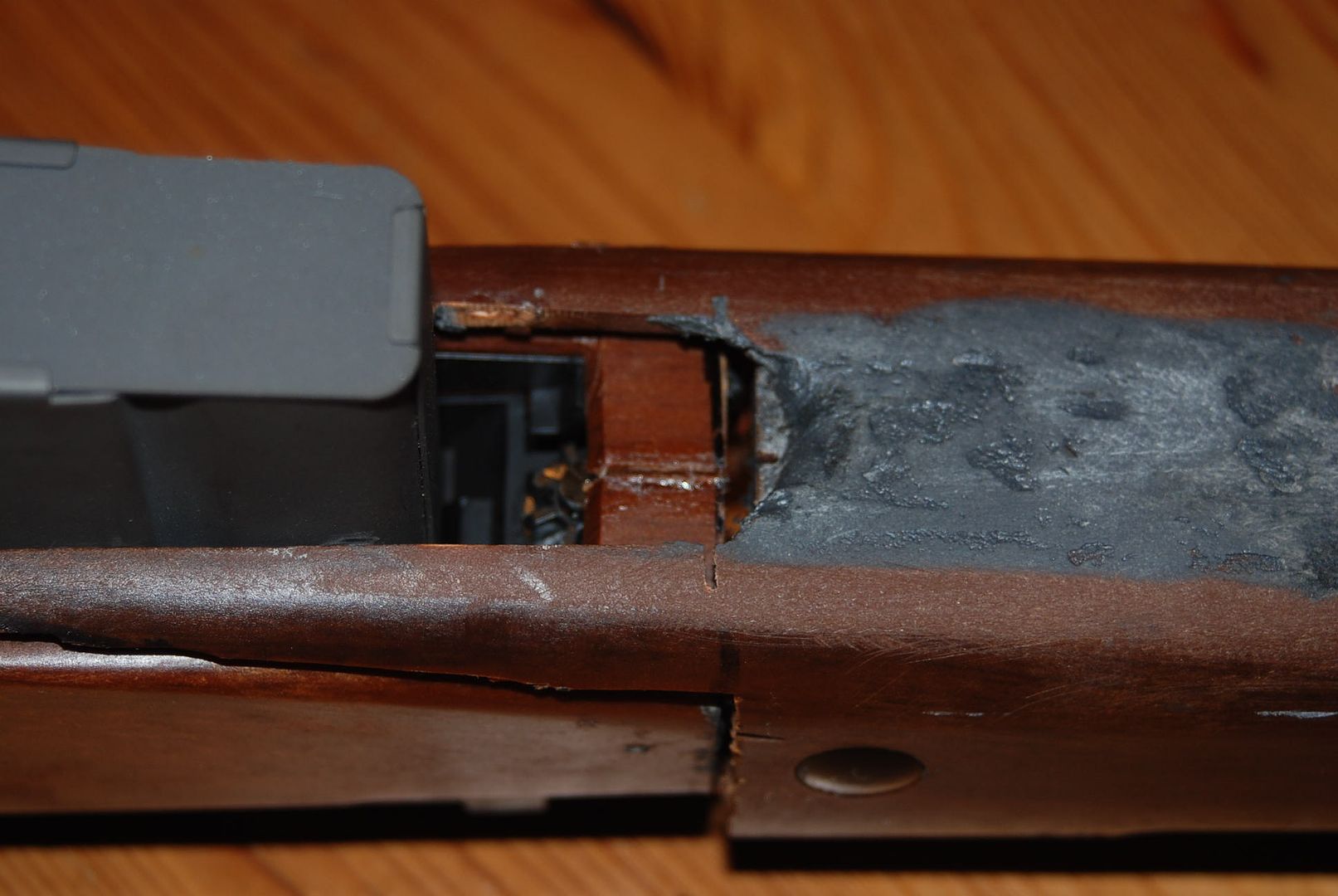

Post by insterburger on Oct 10, 2015 18:09:35 GMT -5

I think I will use what I have on there now, which is a beat up No.4 Enfield upper hand guard. It's a scoche short and not too meaty, but it should be a ton less work than modding the removed M14 forend and I think it looks OK... my 98k builds are intended to be "faithful recreations", but given the limitations of what I have to work with, this will be more like an "evocative suggestion." Some more details: The front of the magwell as it stands. This will be built up with fiberglass or epoxy.  Cut off the selector switch and notched it. In the field I will want semi all the time (have a MOSFET lying around somewhere for this project), but if I ever need to run full auto, I can do so with the turn of a screwdriver.  The stock will be difficult-- the two pieces have a different top plane, I will need to cut out/fill in the M14 section to make them similar. Haven't figured it out yet, as I can't cut away too much of the side rails on the M14 body or completely eliminate that plane, as they determine how the action sits in the stock and will foul up my magazine function if I screw with it.  |

|

|

|

Post by insterburger on Oct 10, 2015 18:12:39 GMT -5

Disassembled where the stocks will attach. Two threaded bolts are epoxied into the M14 part. I will fill the holes on the forearm with PC7 and join them, which should be very strong, then will build up (hopefully with fiberglass) once it's dry and stable.  |

|

|

|

Post by insterburger on Oct 10, 2015 18:15:06 GMT -5

FWIW, a detail where the M14 barrel fairing joins the action-- I was successfully able to cut out the ENTIRE M14 receiver, and replaced the bits that hold the screws with simple nylon-bushing nuts.  |

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Oct 11, 2015 11:48:09 GMT -5

Excellent and creative work. Nice to see you jump back into this.

|

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Apr 2, 2016 14:44:13 GMT -5

On my G43 build which was inspired by this and other builds I ended up using a section on M14 stock as my handguard/ heatshield although I found it was too tall so I cut away about 1/4 inch from what WAS it's top plane. I then used those removed strips to create a higher top plane on my extensively modified lower stocks to build up their height where needed. Once blended in with dyna glass, sanded and finished those strips worked very well.

My build is certainly not as thorough in its attempt to be correct but your efforts certainly inspired me to get it going and get it done. Incidentally I found I had to add length to my stock and upper hand guard as my initial effort over a few days just made me crazy. Now my front stock band is making me crazy.

|

|

Jerry-ADK

Private 1st Class

Unteroffizier, Heeresgruppe Nord-Ost

Unteroffizier, Heeresgruppe Nord-Ost

Posts: 418

|

Post by Jerry-ADK on Apr 8, 2016 13:12:36 GMT -5

I noticed that earlier in this post people mentioned 3D printing technology for creating a mock up the receiver group. Why not just carve it out of maple or some other hard wood? If its just dummy anyway. It could then be reinforced with epoxy and Painted black. you shoud be able to achieve a proper look alike that way.

|

|

|

|

Post by aldrich on Apr 9, 2016 0:38:00 GMT -5

I think there is someone in the UK that sells rubber upper receivers for g43/m14 conversions. "Shoot and Scoot" is what they are called I believe.

|

|

Jerry-ADK

Private 1st Class

Unteroffizier, Heeresgruppe Nord-Ost

Unteroffizier, Heeresgruppe Nord-Ost

Posts: 418

|

Post by Jerry-ADK on Apr 9, 2016 9:01:53 GMT -5

I think there is someone in the UK that sells rubber upper receivers for g43/m14 conversions. "Shoot and Scoot" is what they are called I believe. Yes, I have looked at that site, they do have a resin cast G43 upper receiver. But it cost 60 quid plus shipping. Which would probably be over $100 by time you get it. I do like what Shoot and Scoot are doing by offering kit Enfields and other WW2 airsoft related items. In Europe airsoft entrapaneurs can have a go at doing a business like that because many people do WW2 airsoft. Maybe somebody over there will offer a M14 to G43 conversion kit someday. |

|

2nd Bat

Master sergeant

Posts: 11,813

|

Post by 2nd Bat on Apr 9, 2016 12:44:58 GMT -5

There are both finished G43 rifles and kits to build your own through a company in Wales called Vintage Airsoft. Like Shoot n Scoot they offer a number of products in support of WW2 Airsoft. They show a nice step by step showcasing their build process. Their laminated stocks required clearly a lot of time and effort. They sell via ETSY but I had trouble accessing availability or pricing.

The end result based on pictures was on Parr with most of the homebuilders attempted here from our assorted builders. Not as nice as Gryphon's (IMO) and limited by the M14 internals. It will be interesting to see how well it sells.

|

|