|

|

Post by thatoneguy92088 on Aug 22, 2010 18:33:34 GMT -5

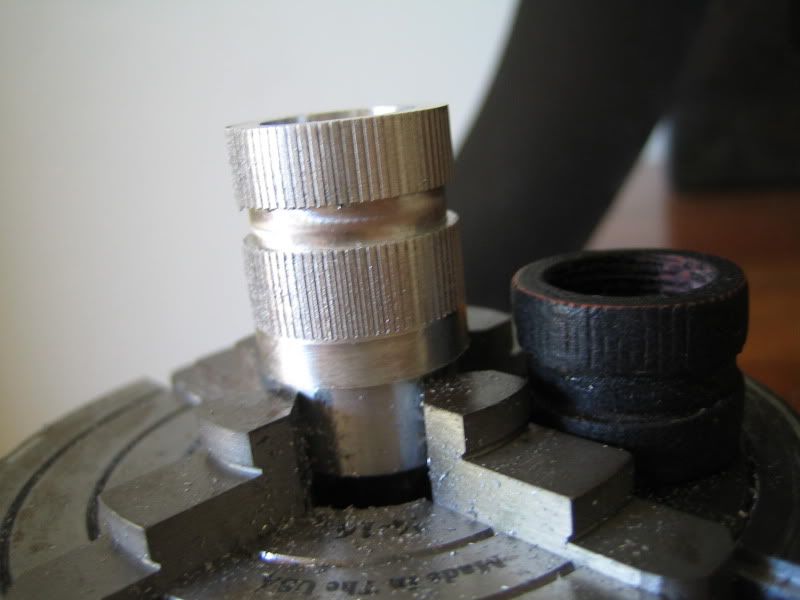

I just made an mp40 barrel nut on the mill and I think it looks great. Heres a picture with the standard plastic one.   The only problem is the tap I have to get in order to thread the nut. Being x1.0 mm it threading is different than the standard 1.25 mm that is available locally for cheap and the only sized taps that are right are around 40 which is a lot for something I'm only going to use once. I'm wondering if anyone had a better idea where to get the right tap? |

|

|

|

Post by CharleyNovember on Aug 22, 2010 19:56:44 GMT -5

Make more than one and sell a couple at a reasonable rate. That way you get one for you and maybe make a few extra dollars over the cost of the project.

|

|

|

|

Post by thatoneguy92088 on Aug 22, 2010 21:24:18 GMT -5

Would anybody be interested in a few if I could make a few of them? They would be machined out of aluminum and could either be painted black or left unfinished and should fit the AGM MP40. How much is reasonable, $40?

|

|

|

|

Post by overlord on Jul 19, 2011 16:32:36 GMT -5

Did you ever make any of these for sale? Or does anyone know where I can get one? I don't care if it is metal or plastic. Thanks.

|

|

|

|

Post by no1sonuk on Jul 20, 2011 17:33:30 GMT -5

When I made mine (see attached), I used a lathe. Dead easy to make an M14 x 1mm thread that way. Same 60 degree tool you guys would use for UNC threads, just a different depth and leadscrew ratio. Then again, I'm in the UK, where metric tools are easy to come by, and I have an M14 x 1mm spiral flute tap on its way to me in the post now. My procedure: Face end of bar. Part off length for nut. Reverse in the lathe and face to length. Drill 13mm hole (yes, metric IS that easy- the drill hole size is the outer thread diameter minus the pitch). Tap hole to M14 x 1mm. Fit on M14 x 1mm steel mandrel. Turn down to diameter. Straight Knurl. Turn groove. Done... The steel mandrel I mentioned above is a steel bar that fits in the lathe chuck, with an M14 x 1mm thread to fit the nut on so that it can be turned down after threading. The threading operation needs a solid grip that would probably crush the thin walls if it was turned down first. It also allows the knurling to be done when the nut is its final length. Attachments:

|

|

|

|

Post by BigBoy on Aug 7, 2011 8:16:44 GMT -5

When I made mine (see attached), I used a lathe. Dead easy to make an M14 x 1mm thread that way. Same 60 degree tool you guys would use for UNC threads, just a different depth and leadscrew ratio. Then again, I'm in the UK, where metric tools are easy to come by, and I have an M14 x 1mm spiral flute tap on its way to me in the post now. My procedure: Face end of bar. Part off length for nut. Reverse in the lathe and face to length. Drill 13mm hole (yes, metric IS that easy- the drill hole size is the outer thread diameter minus the pitch). Tap hole to M14 x 1mm. Fit on M14 x 1mm steel mandrel. Turn down to diameter. Straight Knurl. Turn groove. Done... The steel mandrel I mentioned above is a steel bar that fits in the lathe chuck, with an M14 x 1mm thread to fit the nut on so that it can be turned down after threading. The threading operation needs a solid grip that would probably crush the thin walls if it was turned down first. It also allows the knurling to be done when the nut is its final length. I like your idea for the AGM MP40 muzzle nut and I'd like to make one too. When you straight knurlled the outside, what was the pitch (threads per inch) of straight knurling tool you use? I've looked at the staright knurling tools and they come with many different pitches. They have pitches of 14, 16, 25, 30, 40, 50 and 114. Perhaps I can't get exactly the same as you used because with you being in the UK, it is probably metric. However, being close to what you used will probably work. Thanks. |

|

|

|

Post by no1sonuk on Aug 7, 2011 12:53:05 GMT -5

The pitch of the one I used is about 1mm, so I guess "25" from your list would be closest, assuming it means 25 per inch. 30 might give you better tolerance on the diameter.

|

|

|

|

Post by BigBoy on Aug 8, 2011 5:58:53 GMT -5

Thanks for the infomation of the pitch of the straight knurlling tool.

I find it strange that AGM would make two muzzle nuts with different threads. I have an AGM MP44 and the muzzle nut thread is a LEFT-HANDED (CCW to tighten) thread while according to the posts above, the MP40 Muzzle nut is a RIGHT-HANDED (CW to tighten) thread. If you look at the outside of the MP44 and MP40 oragnge muzzle nuts, they appear to be very similar. I wonder why AGM would make one left and the other right handed threads? It would seem to me to complicate their manufacturing and inventory process to have two nearly identical parts with different threads.

|

|

|

|

Post by no1sonuk on Aug 8, 2011 14:34:23 GMT -5

Pure speculation follows:

I've been told the MP40 is a copy of an earlier one, so I guess if that was made with RH thread, so was the copy.

As far as I know, the MP44 isn't a copy, or if it is, the original was from a different source.

I can't find where I read it, but I think the MP40 nut should be LH too. Also, I think the originals were 16mm threaded, rather than 14mm.

|

|

|

|

Post by BigBoy on Aug 8, 2011 15:05:57 GMT -5

The real MP40 muzzle nut is 15mm in diamter with 15x1.0mm Right-Handed threads with 72 V-groove serations around the circumferance of the nut. The AGM MP44 orange muzzle nut has Left-Handed threads, 14x1.0mm. The real MP44 has Right-Handed threads, 14x1.0mm. I've attached pictures of the MP44 muzzle nut and ones I make. They have 16 grooves around the circumferance of the nut. Attachments:

|

|

|

|

Post by no1sonuk on Aug 8, 2011 16:46:22 GMT -5

Ball nose end mill?

|

|

|

|

Post by BigBoy on Aug 8, 2011 16:59:11 GMT -5

Yes, I used a 5mm diameter ball nose end mill to make the flutes on the MP44 nuts.

|

|